BUILD, BOOST AND TRANSFORM

BELGIUM

Europe's heart on the way to a sustainable economy

By Marcia de Troyer, Vice President and Co-Taskforce leader of Sustainability

Between the English Channel in the west and Germany in the east, the Benelux countries Belgium, the Netherlands and Luxembourg are home to Europe's most important hubs for world trade. All three nations have in common that they are small in size but extraordinarily strong economically. Belgium, for example, is not only one of the world's largest exporters, but as a European trade center it also has one of the densest infrastructure networks on the planet – with about 200 ports and an xceptionally high percentage of inhabitants (98%) that belongs to the urban population. With Brussels, the capital of Europe, the country is also a hotspot for dynamic, internationally active companies and groups.

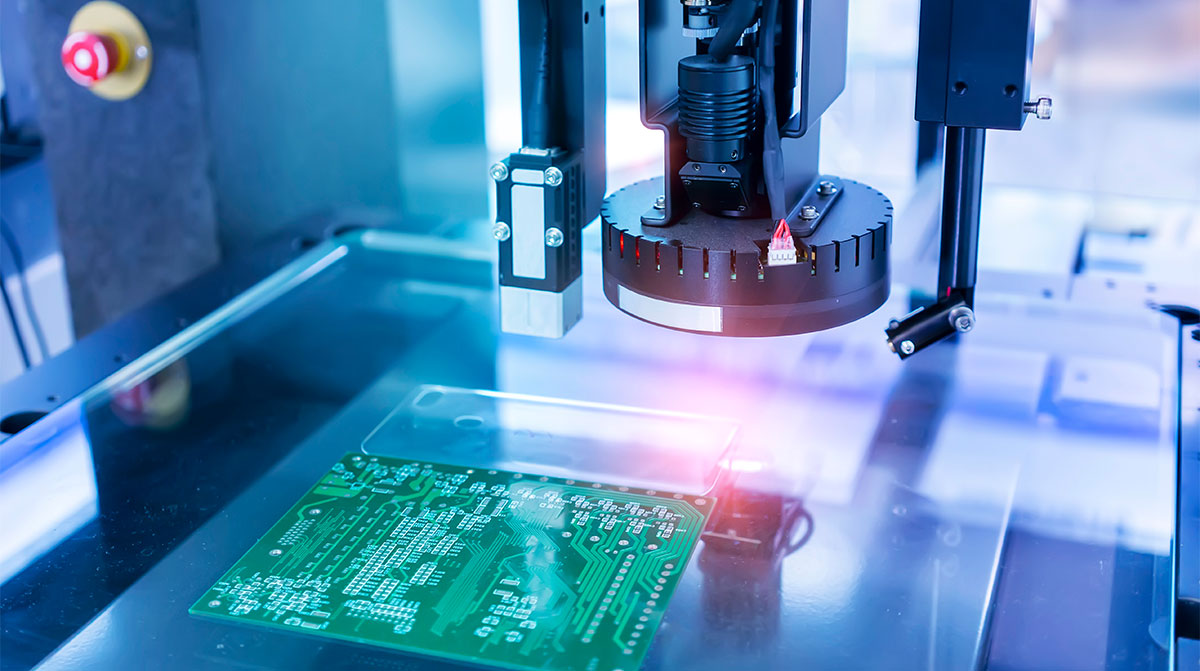

The dynamic and broad industry portfolio of these players is reflected in the orientation of the local consulting market. Certain consultants tend to combine generalist and specialist know-how. That means they can be deployed in a wide variety of projects – whether it be chemicals, discrete manufacturing, food and beverage or infrastructure companies like Infrabel or the Port of Antwerp-Bruges – and they can also go in depth or work with experts. Accordingly, the majority of our Belgian consulting projects has a strong international reference and address a wide range of topics, on operational excellence as well as extensive transformation projects, M&A, or major change programs. Analytical projects are also carried out, e.g. data analysis to improve supply chains. In this respect, our local office has a rather generalist profile with very different types of projects. Nevertheless, we are currently observing two exciting aspects that our customers are facing: the potential of digitalization in terms of sustainability and how to boost organizational transformation.

Combining sustainability and digitalization

For our economy, the European Green Deal is one of the key drivers for sustainability. This concept, presented by the European Commission in 2019, sets the goal of reducing net greenhouse gas emissions in the European Union to zero by 2050, making it the first continent to become climate neutral. Of course, there are big differences in the way companies deal with this and with other sustainability topics as well. Many of them are currently reinventing the way they do business and are taking accelerating measures to reduce their greenhouse gases. Here, in particular, connection with automation, digitalization and sourcing the right data, as well as the close networking of partners in the value chain prove to be as important measures.

On top of the ongoing, more traditional continuous improvement programs, we’re noticing a drastic increase in transformation and change programs lead by and in in the R&D/corporate development departments of our clients. So, there’s a clear change to a new course to become climate neutral by 2050, which wouldn’t be possible by only sticking with the traditional improvement programs and measures.

At the same time, we observe a surge in very focused energy improvement programs with specialist partners who work in an EPC or ESCO model. A strong driver here is of course the drastic increase in energy cost all over Europe, that requires new, short term energy efficiency gain.

Another challenge in this context is how to link the long-term sustainability strategy targets and the more short-term operational results, that operations departments need to achieve yearly, monthly, weekly and daily. Setting up the right cascaded dashboard and performance management supported by an adapted data capturing and management approach is crucial here.

Also, the human dynamics part can improve a lot to meet these challenges. For example, enhancing cross-company and cross-department collaboration or ensuring openness to digital solutions. To unify these perspectives, many companies could already achieve more with digitalization. For example, some logistic providers could manage the transport flux in a more automated way, but solutions are delayed due to job protection or political reasons. In plants, automation solutions are sometimes turned off as workers find it hard to accept that a machine is doing something they have done themselves for years or don’t trust the solution and fear for their safety. This clearly confirms our position, that digitalization / Industry 4.0 are not just about attaching sensors and collecting data, it's also about getting people to embrace the new digital processes. At interfaces, where human dynamics and digitalization meet, we do a lot of change projects to get people to accept the change.

In sustainability, there’s a shift towards change

and transformation programs.

Exploiting new transformation paths

These issues are, of course, closely linked to the second major topic: changing organizations in such a way that they can master new challenges as well as mobilize economic resources quickly. In the past, EFESO was known for so called “build programs”, e.g. building traditional lean programs or analyzing, planning, implementing large improvement programs, including employee’s skill trainings. But today, companies need a faster return on investment. So, we defined “boost programs” which can pursue different objectives. For example, achieving first results in manufacturing lines within 8-12 weeks, which brings in money for further investments. Or, with a more disruptive transformation approach, automation programs for factories.

Regardless of project goals, EFESO consultants are seen as transformation partners who support the CEO, COO or line managers to make things work. There is a relationship of trust, which is expressed through many long-standing client relationships. In cultural terms, we're all quite pragmatic: “just making things work” is an attitude that is often encountered in our region. In Belgium, clients and consultants are motivated as well by the results that they get as by the process of getting there. And of course, we are a global company ourselves – our country teams often work closely together to find the best solution for the client, and they complement each other very well.

EFESO reference project from Belgium: Port of Antwerp-Bruges

The Port of Antwerp-Bruges, the largest seaport in the EU, has to face several challenges at the same time: In an increasingly competitive and unstable international market, it is always a question of ensuring further growth – while being able to respond to the growing influence of different interest groups. In addition, there were congestion problems associated with increasing traffic volumes during the time of the project. Above all, the focus was on mastering the organisation of the transformation from a linear to a circular economy.

Challenge

In an increasingly competitive and unstable international market, the Port of Antwerp-Bruges needs to realign its positioning from a monopolistic government institution to a stakeholder-driven "community builder".

Approach

Together with Extended Leadership Teams (ELT), the project team develops a "Leadership Journey" to define the future cultural framework as a basis for the transformation process and tests it in pilot projects with different stakeholders.

Success model

"Leadership Journey" to jointly define and implement the future cultural framework (strategy cycle process, winning teams, leadership, etc.) to quickly achieve first positive results.

Learn more from the detailed case study.

EFESO clients: some of our key projects in the Benelux market

- Key industries are chemistry, food and beverage, infrastructure services (with clients like Port of Antwerp-Bruges, the Belgian electricity system provider, the Belgian railway company). A major focus is on large-scaled transformation projects like the company merger of the port of Antwerp and Zeebrugge. Furthermore, we support chemical companies in terms of improving their operational excellence and advanced analytics capabilities.

- We also work for one of the leading copper producers in the world, located in Germany. At its Belgium site, we improved processes regarding to human dynamics, digitalization and Industry 4.0.

- With some client we boost sustainability / green programs, e.g., working with the R&D department to develop breakthrough solutions, with the CEO / COO / Innovation VP to boost involvement of the different departments or in the definition and execution of the GHG reduction roadmaps.

- Accompany a worldwide innovation leader in the semiconductor industry, in better and faster bringing changes to 12.000 engineers in order to support to rapid growth.